Machining Capabilities

We Create Complex Precision Parts for Your Toughest Projects

When it comes to leveraging technology to create your precision parts, IQM Solutions is equipped to handle your needs. From innovative technologies to our highly trained machinists, our team is ready to take your project from concept to reality. Send us your toughest parts, your most unique challenges, and watch our team surpass your expectations.

Multi-Axis Machining

Multi-axis machining tackles complex parts with accuracy and cost reduction. This advanced technology reduces production time by machining from multiple angles with minimal setups. By minimizing setups, it also ensures exceptional accuracy and consistent quality. Multi-axis machining can deliver smoother surface finishes and potentially eliminate extra machining operations. This typically results in faster turnaround times, higher quality parts, and a lower per piece cost.

CNC PROGRAMMING

We leverage the power of a leading CAM software to bridge the gap between your design team and the finished product. This translates to faster turnaround times and reduced costs. To guarantee flawless execution, we utilize advanced verification software and a rigorous management approval process. This minimizes machining delays and ensures your parts are built exactly as designed, the first time.

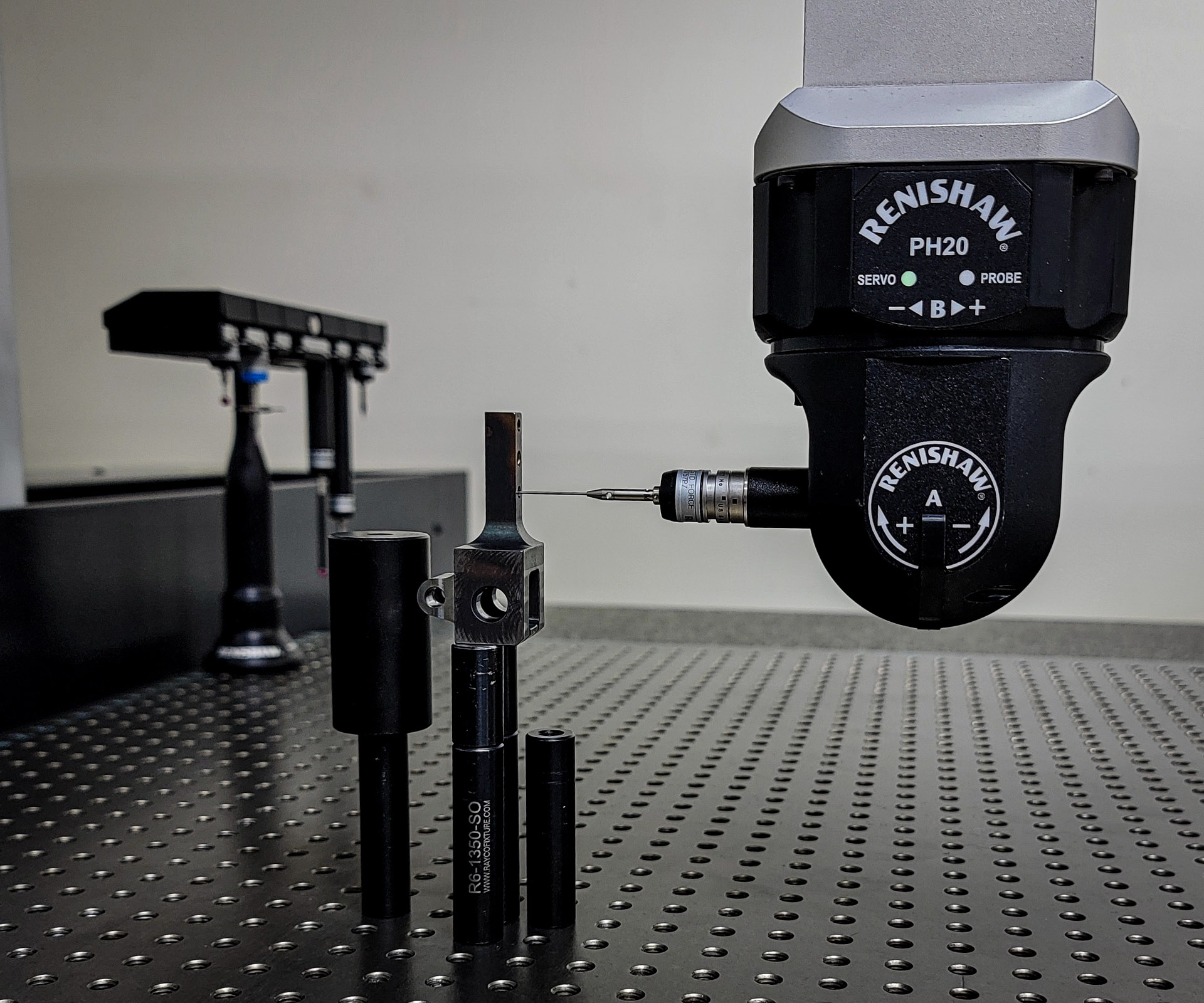

5 axis cmm programming

Utilizing top-of-the-line CMM software our inspections go beyond simple measurements. We leverage our extensive knowledge of Geometric Dimensioning & Tolerancing (GD&T) to ensure our quality is repeatable. Understanding how parts are manufactured, our processes identify potential issues before they arise. Finally, optimized programs minimize inspection time, streamlining your quality control process. The result? Clear, efficient inspections that deliver complete confidence in the products you receive.

Full Service Quality Lab

From in-house calibration to expansion of new inspection equipment, our machinists and inspectors are up to the task. Our inspection process and tools mirror your expectations. Whether its inspection certificates, calibration, or process qualifications, we ensure compliance throughout the entire process.

Grinding, brazing & welding

At times, grinding, brazing and welding experience can be a challenge to source. Our experience in surface grinding covers a wide range of production needs. Our partnerships with local CNC grinders and welders make quick turn around time and ensure products meet your qualifications.

quality Prototyping

From quoting to building the manufacturing process to working through design challenges, our experience is in supporting engineers with the right equipment, manufacturing knowledge and service. For quicker turnaround times on prototype orders, we stock a wide range of standard materials and sizes along with a large selection of cutting tools and specialized equipment for part finishing and assembly.

Looking For A Quote?

If you’re ready to start your next project then we would love to hear from you. Head on over to our quote page to get started.